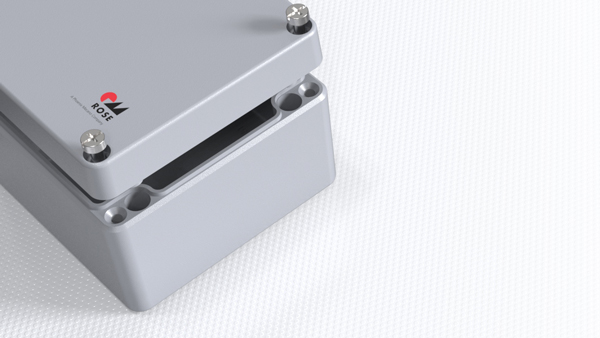

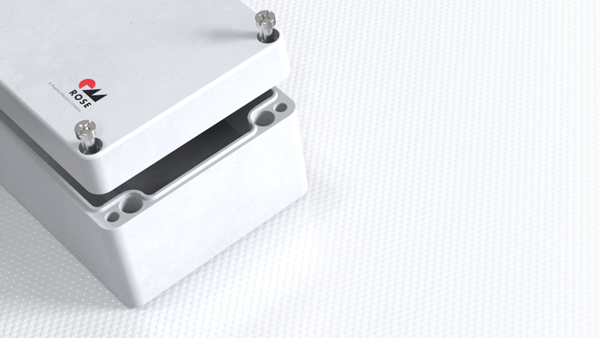

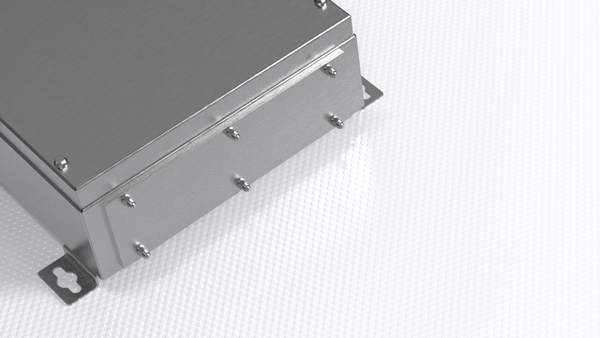

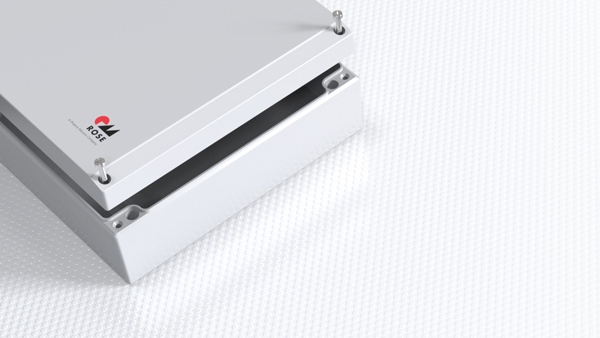

Enclosures for railway technology

(HL1 to HL3)

Rail vehicles have been used to transport goods and people for over a century. Due to population growth in metropolises and the transport revolution, rail transport has developed rapidly worldwide and now links cities all over the world. Enclosure systems from ROSE are used here to protect safety and functionally relevant technology in order to guarantee trouble-free operation. This makes them an important part of the railway industry.