Aluminium Enclosures for electronics by ROSE: Versatile and robust

ROSE Aluminium Enclosures enable electrical and electronic equipment to continue working reliably for years and years under adverse ambient conditions. The properties of aluminium as a material, and the high-quality material alloy from which our enclosures are manufactured, assure a product which convinces with its reliability and quality in adverse environmental conditions in particular.

Our aluminium enclosure systems can be used in zones of exposure to corrosion without any additional coating treatment. They possess excellent resistance to the aggressive fluids encountered in industry, including moisture, vapours, alkalis and oils, for example. On request, a special seawater-resistant paint finish can be applied to our products for applications in salt-bearing atmospheres.

These robust aluminium die-cast enclosures are eminently suitable for the installation of electromechanical components.

AluForm enclosures are aluminium die-cast enclosures for use in C&I and automation system technology.

Aluminium Enclosure: Ready made on request

We equip all enclosures optionally with the following components:

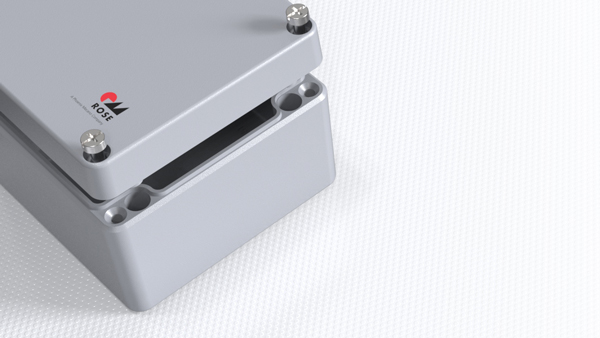

The spring-groove principle of our aluminium enclosures guarantees absolute sealing

To prevent damage to the sensitive electronic components, not only the wall of the enclosure should be extremely robust. Equally important is an effective sealing of the enclosure joints to the outside. Therefore, all enclosures from ROSE are designed according to the spring-groove principle and are equipped with PUR or CR seals. The installation of VMQ (silicone) seals is also possible. Our aluminium enclosures meet the criteria of protection classes IP66 (Aluminium Standard and Aluform) as well as IP67/IP69.

What are the advantages of our aluminium enclosures?

Since 1969 ROSE has been developing and producing high-quality industrial enclosures and system solutions for the mechanical and plant engineering, automation and instrumentation & control industries as well as for the food industry and hazardous areas. In addition to standard enclosures made of aluminium, stainless steel and plastics, we also manufacture operator and display enclosures for HMI applications.

As enclosures made of aluminium were the product with which we first entered the market, we have great expertise in processing this material. This is one reason for the outstanding quality of our aluminium terminal boxes and for their widespread use in industry. But there is another: Their special construction. Separate screw fastening channels integrated into the housing form prevent the electronic components from being damaged by chips when the cover screws are screwed in. And they allow full use of the installation space in the housing.

We manufacture our aluminium housings watertight. You also have the option of receiving custom-made aluminium enclosures, which we supply unmachined as well as partially or completely assembled.

How are the aluminium enclosures manufactured?

- Production using a modern die-casting process

- Therefore high housing quality and

- more economical finishing than with gravity die casting

What processing options are available for aluminium crates?

Surface refinement through powder coating

What materials do we use to build our aluminium enclosures and why?

We use a high-quality aluminium alloy with a low copper content [AC-AlSi 12 (Fe)]. This gives us a high level of corrosion protection and allows us to optimally machine the enclosures after production. The alloy also offers good chemical resistance and allows the enclosures to be used in a wide temperature range.

Aluminium case manufacturer ROSE: Everything under one roof

Our production in Germany has many advantages for you as a customer: On the one hand, we can guarantee you a very high product quality. On the other hand you benefit from short delivery times. Modern machinery, more than 50 years of experience in the production of aluminium enclosures and an effective QM system – these are only three of many good reasons to choose an enclosure from ROSE. With us you will get the optimal solution for your application.

What makes our aluminium enclosures so special?

- External mounting channels for cover screws and wall mounting ensure a tension-free installation space

- The spring-groove system guarantees absolute sealing

- All enclosures have at least IP66/IP67 protection class as standard

- By using different seals, the protection class or resistance to chemicals can be increased (e.g. EPDM, silicone)

- The enclosures offer comprehensive basic EMC protection

- They are impact resistant to 10 joules (IK09)

Aluminium enclosure from ROSE: The bestseller for 50 years

Our standard aluminium enclosures are in great demand on the market, and there are good reasons for this: They are robust, universally applicable and available in numerous sizes.

What we do for you

Scope of delivery

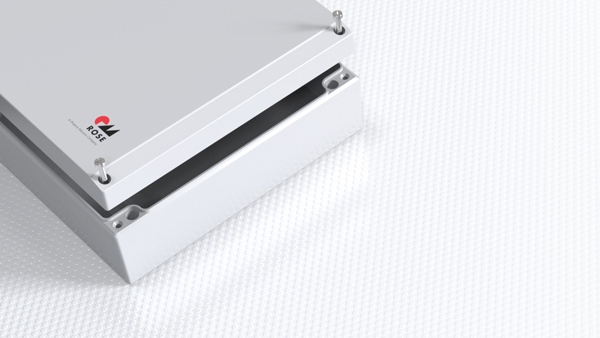

ROSE aluminium enclosures consist of a cover including gasket and captive +/- stainless steel screws as well as a bottom part with 2 or 4 earthing screws

Assembly

We would be pleased to take over the partial or complete assembly/installation of your enclosures.

Our services:

- Assembly

- Simple installation of electrical components (e.g. terminals, mounting rail)

- Main assembly

- Modular cable assembly

- Full or partial wiring

- Control cabinet construction

- Circuit board assembly

- Gluing in membrane keyboards and viewing panels

- Electrical inspection

- Final acceptance

How to order custom-made aluminium enclosures quickly and conveniently

To receive your custom-made aluminium enclosure, simply fill out the order form that is displayed for the respective aluminium enclosure version. We will send you your personal offer within the shortest possible time.