ROSE enclosures for agriculture and agricultural technology

The food industry is known for its innovative technologies in the processing of raw materials and the production of food. Starting with agriculture, the most efficient and modern agricultural technology is needed so that farmers can produce and process enough food with the least possible effort.

Modern sensor technology, satellite-based GPS orientation and other robot technologies are just the beginning. To ensure that the sensitive electronics in these advanced tools are not exposed to the harsh agricultural environment, they are reliably protected by the robust housings from ROSE Systemtechnik. Typical areas of application include tractors and other agricultural machinery, milking systems, feeding systems and biogas plants, as well as inclined conveyors and livestock barns.

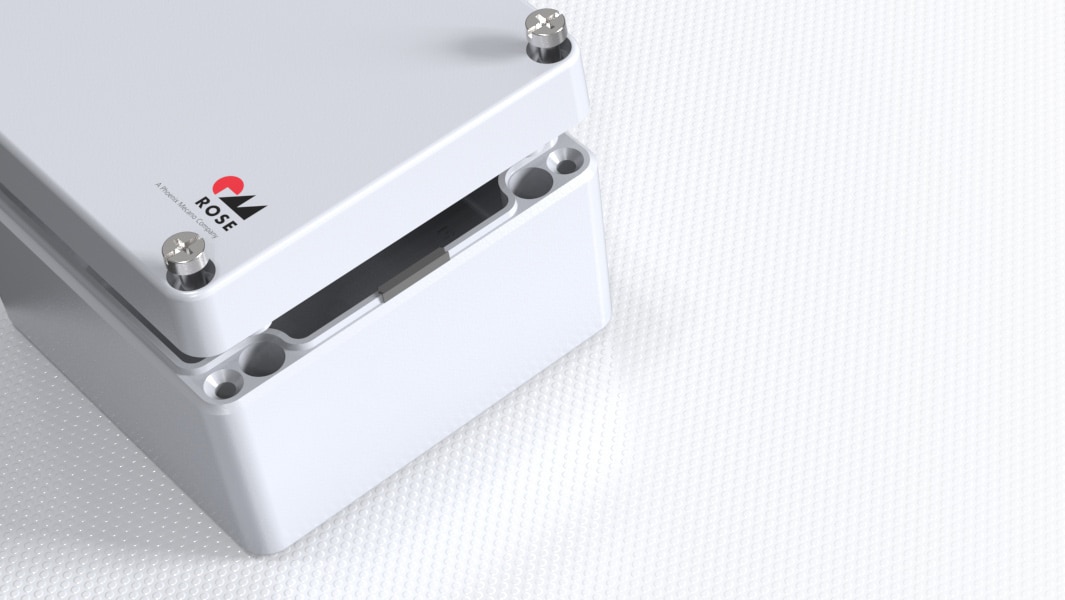

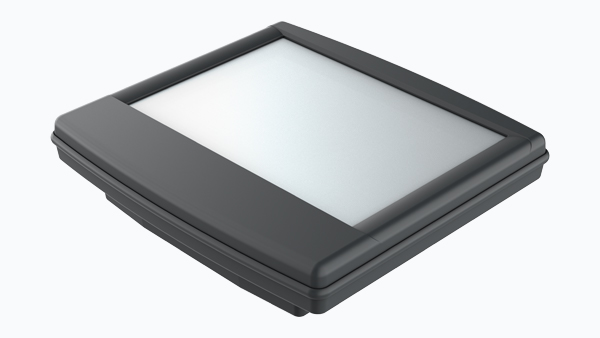

Our industrial, display and operating enclosures for the various applications withstand vibrations, dust and moisture. Even thorough cleaning, as required in the food industry, is no problem with the right enclosure.

Further information

We manufacture enclosures for all applications for these purposes:

This is where ROSE enclosures are used in agricultural engineering

Industrial enclosures for digital agriculture

Explosion protection housing for digital agricultural technology

Customised special enclosures for your agriculture

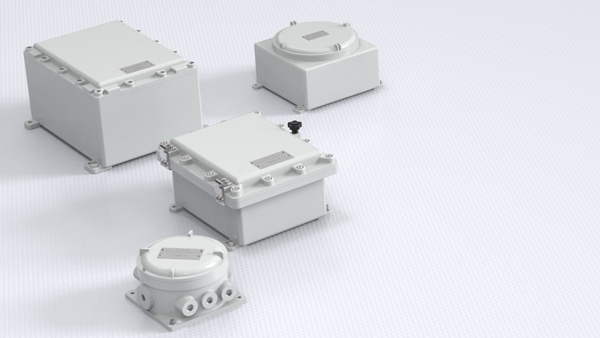

Explosion protection for biogas plants with Ex Control Stations

Manufacturers and operators of biogas plants must take effective measures for explosion protection. However, the formation of an explosive atmosphere and the presence of ignition sources cannot be completely avoided due to the circumstances. For this reason, the enclosures of the electrical equipment must be designed in such a way that their components do not pose a risk of explosion. With its Ex enclosures, ROSE Systemtechnik offers the ideal solution for such applications.

Ex d enclosures protect equipment in biogas plants against moisture, dirt, dust and water (protection class IP66)

The control points have a flameproof Ex d enclosure that prevents the spread of an internal explosion to the surroundings. An explosion could occur, for example, if an explosive atmosphere from the system enters the enclosure and is ignited by sparks.

To prevent such an explosion from spreading to the surrounding atmosphere, an ignition gap cools the fumes before they escape. In addition, the outer wall of the stainless steel or aluminium housing can easily withstand a pressure wave.

Another advantage of Control Stations with Ex d enclosures is the perfect protection of the equipment installed in them against moisture, dirt, dust and water (protection class IP66). Ex d enclosures from ROSE Systemtechnik are available in various sizes and designs. Before delivery, they are subjected to so-called overpressure tests, which ensure the robustness of each individual enclosure. In addition, ROSE offers numerous enclosure-related services, such as mechanical processing, painting, special coatings, engraving and printing.